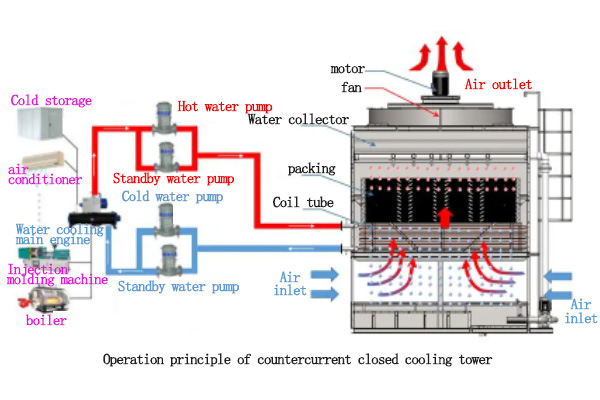

Working principle

This series of cross flow glass steel cooling tower adopts air inlet on both sides, relying on the top of the high performance fan, so that the air through the filler on both sides of the tower, and the hot and humid air is discharged to the outside of the tower. The filler adopts the point wave plate with convex points on both sides, and the point wave plate is bonded into a whole through the installation head to improve the rigidity. The convex points on both sides can also avoid direct dripping, so as to improve the water film formation ability. The filler tail is provided with water collection measures.

Design features

1, save space, light structure

The efficient heat exchange material specially designed for the cooling tower of this series is used. The heat exchange area is greatly improved. Compared with the original HBLD series and the original HBLCD series, the floor area is greatly reduced.

2, good corrosion resistance

Tower body, sink and panel are made of FRP material with good corrosion resistance, and add light stabilizer in gelcoat resin, has good aging resistance, durable without discoloration. The steel structure parts of the tower are treated with hot-dip galvanized after processing to improve the corrosion resistance of the cooling tower. In the normal service life, there is no need for additional anti-corrosion.

3. Combined design

The combined design makes the selection of engineering and using units more flexible and practical, the delivery of the manufacturer faster, the installation unit assembly more convenient, and in actual use, it can automatically open and close the cooling tower body according to the increase or decrease of potential source, to achieve more energy saving.

4, energy saving

Low wind resistance cooling packing with unique streamline design of the air duct and large blade of high efficiency fan, greatly save the motor power consumption.

5, durable

The tower body is made of reinforced glass steel, which prevents corrosion and reduces maintenance and repair costs. All the tower support is made of thick steel, and through hot dip zinc treatment, to meet the national standard, durable.

6. Low noise

Large blade and streamline design of the fan blade, coupled with low speed operation makes the fan especially quiet.

7. Easy to assemble

Combined design, lightweight accessories make transportation and installation easy.

The features of the components of the cross-flow cooling tower are introduced

1. Adopt professional waterproof motor, protection class up to IP55, motor shaft chrome-plated rot, insulation class F. The electric machine has the advantages of low noise, low vibration, wide voltage, high efficiency, sealing and waterproof, rated voltage: 380V, frequency 50HZ.

Special fan for cooling tower, advanced aluminum alloy material, with wide blade and wing hollow blade design. High air volume, low noise, high efficiency, low energy consumption. It has a scale for manual adjustment of fan Angle. With Liangyi high-strength wind LM, streamlined design, smooth air out.

Three, the water distribution device adopts gravity type water distribution design, FRP water tank design. According to the different flow rate, each specification of the water tank water aperture, the number are different, so that the liquid level of the water tank is consistent, the design of the water between the water tank and the filler, further disperse the water flow, so that the water on the heat dissipation material more uniform distribution.

Four, the reducer adopts belt drive, smooth operation, low noise. The upper and lower cover of the belt box is designed to protect it from the influence of external water vapor. FRP material, safe operation, easy to operate and maintain. Adopt advanced imported belt to ensure the use of strength and life.

Five, the outer wave board and water plate of the shell tower body are made of glass fiber reinforced plastic (FRP) material, FRP waterproof resin and non-alkali glass fiber felt, good infiltration, high glue content, high strength, high surface finish, with not easy to fade, anti-aging, anti-ultraviolet, beautiful shape. The air inlet is equipped with the downwind plate, the use of advanced PVC and engineering plastics and anti-UV agent materials extrusion molding, dense and durable, the air to be rectified, and has the function of retaining water.

Six, packing advanced PVC raw material vacuum forming, sheet thickness uniform, high strength and toughness. The selection of opaque, UV resistant materials, combined with the overall slant wave suspension structure, can obtain the maximum heat transfer area and the best air flow through the space, sheet waveform and sheet spacing through strict calculation and testing, high heat dissipation coefficient, easy installation, beautiful.

Post time: Jun-12-2023