01 Difference between condenser and cooling tower

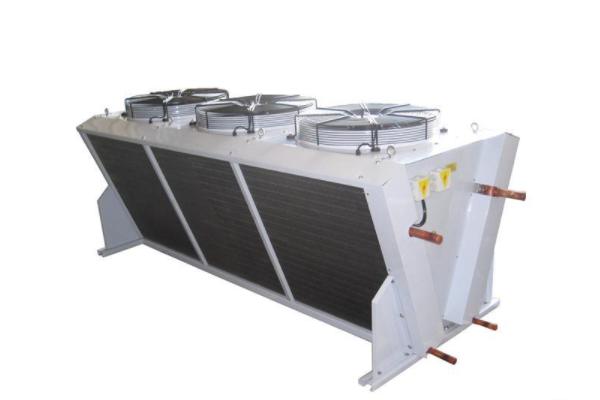

Condenser: A condenser, a condenser, is a condenser of the refrigeration system, belonging to a type of heat exchanger, which can convert the gas or vapor into liquid and transfer the heat in the tube to the air near the tube in a quick manner.

Cooling tower: Closed cooling tower is a device that uses water as a circulating coolant to absorb heat from a system and discharge it into the atmosphere to reduce water temperature; The cold is the use of water and air flow contact after the exchange of cold and heat to produce steam, steam volatilization heat away to evaporation heat, heat transfer and radiation principle to disperse industrial or refrigeration air conditioning generated in the waste heat to reduce the temperature of the evaporation heat device, to ensure the normal operation of the system.

02 Composition of condenser and cooling tower

Evaporative condenser is composed of special axial fan, spray nozzle, electronic water descaling instrument, collecting air bag, PVC heat exchanger, high efficiency dehydrator, cooling pipe group, packing tank, water pump, water collector, box and other components.

The closed cooling tower is mainly composed of metal outer plate, cooler coil, exhaust system, circulating water pump, packing, auxiliary machinery and electric control system.

Evaporative condenser/closed cooling tower can make the water circulation system in the process completely isolated from the outside world, creating a closed and clean operating environment. But in the process of system development, because the closed tower spray system has the characteristics of large flow, low head, so in the selection of spray pump encountered difficulties.

Finally, under the continuous efforts of the technical team developed a stable operation of the system for the cooling spray system of the special pump, adapted to refrigeration, air conditioning, HVAC and other systems, so that the user in the use of energy consumption is greatly reduced.

03 Use

It is mainly used for energy-saving circulating pump series of low head system. Through lean design hydraulic model, advanced production technology and selected high-quality spare parts material, it is more suitable for terminal system.

Application field

1. Water circulation system of closed cooling tower and evaporative refrigerant.

2. Water circulation system of refrigeration unit.

3, central air conditioning/heating and other circulating water system.

Product characteristics

1. New design, fine technology, high efficiency and energy saving, large flow and low head.

2. Compact size: small installation volume, light weight, linear pipe shape, can be conveniently installed in the middle of the pipeline.

3. Quiet design: The motor adopts the outdoor motor with low noise and fully enclosed, anti-splash and dust-proof, which can be installed both indoors and outside.

4. Prevent water leakage: prevent water leakage, durable use, easy maintenance.

5. Anti-rust treatment :LP pump is coated with epoxy resin, so it has a great anti-rust effect.

6 strong structure :LP pump body adopts precision casting, strong and long service life, so the use of circulating pump is the most appropriate.

7. Easy maintenance: the pipeline system does not need to disassemble, you can disassemble and repair the pump, because of the stainless steel bolts and nuts, so there is no need to worry about bolt damage during maintenance, and the disassembly and installation are very convenient.

Installation precautions

1, installation pipe weight should not be borne on the pump, otherwise easy to damage the pump;

2, pump and motor is a whole structure, factory has been corrected by the manufacturer, installation without adjustment, so the installation is very convenient;

3, the installation must tighten the anchor stud, and every certain period of time to check it, to prevent it from loosening, so as to avoid the pump starting vibration and affect the performance of the pump;

4, the installation of the pump should be carefully checked before the pump runner has no impact on the operation of the pump hard objects (such as stones, iron sand, etc.), so as to avoid damage to the flow parts during the operation of the pump;

5, in order to convenient maintenance and safe use, in the pump inlet and outlet pipe on the installation of a regulating valve and a pressure gauge near the pump outlet, so as to ensure that the pump in the best condition of operation, prolong the service life of the pump;

6, pump for suction occasions, should be equipped with the bottom valve, and the inlet pipe should not have too many elbows, and there should be no water leakage, leakage, phenomenon, so as not to affect the suction of the pump;

7. Before installing the pipeline, rotate the rotor parts of the water pump. There should be no friction sound or stuck phenomenon, otherwise, the pump should be disassembled to check the cause.

Post time: Jun-12-2023